Seed Boxes

Bulk Seed Storage Containers

Traditionally corn, grain, resin, seeds, powders, and other flowable materials would be stored and transported in a poly-woven super sack on a wooden pallet. The problems with this method were three-fold: the bags are prone to cuts and tears, stacking the pallets was unsafe, and the bags only lasted a handful of uses.

The plastic hopper bottom container solved all three of these problems: heavy-duty walls protect the product, the containers stack safely four high, and the containers are built for lifetime use.

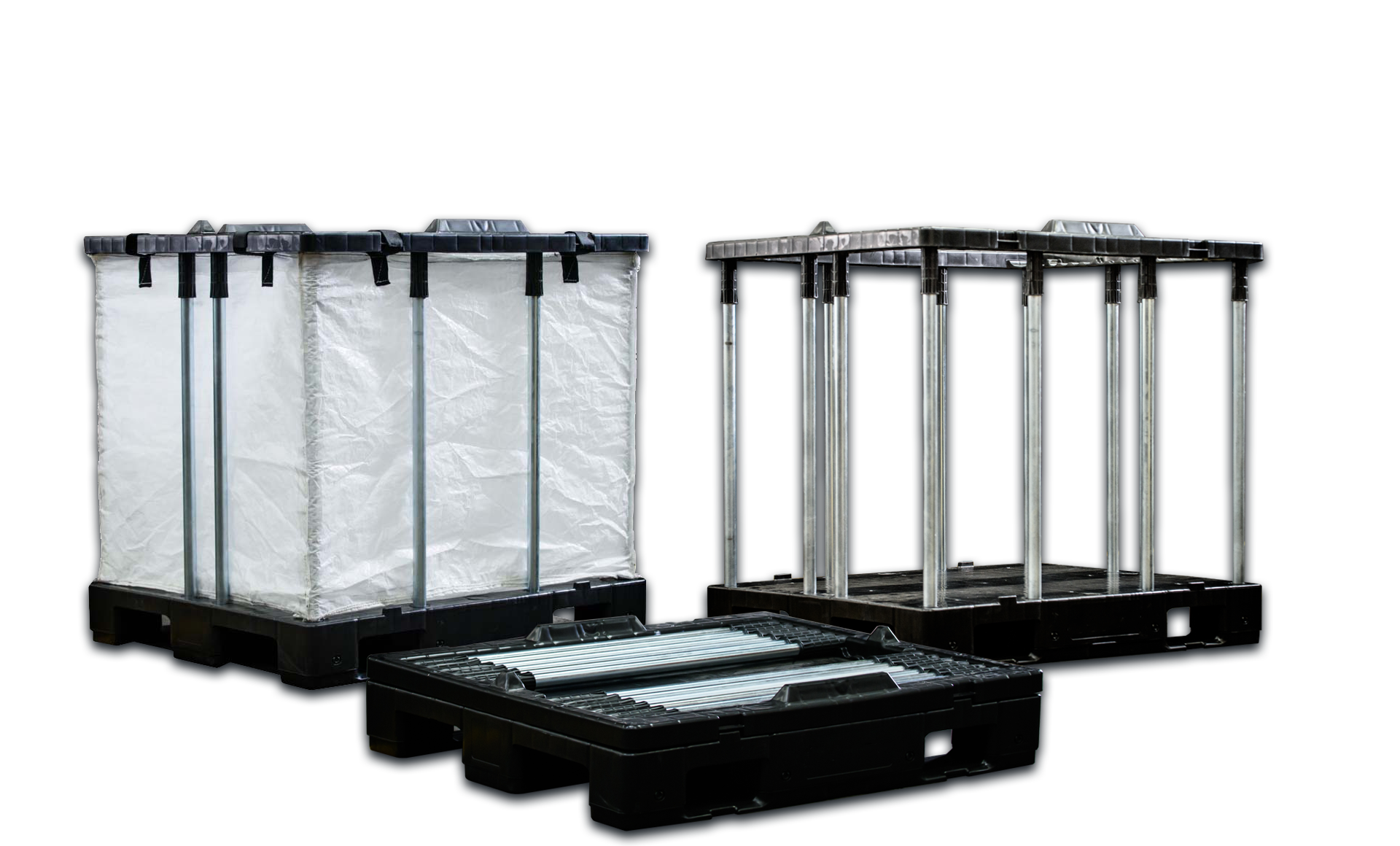

We offer three different styles of seed containers: CenterFlow Hopper Bottoms, Collapsible Hopper Bottoms and the FIBC.