Custom Hopper Bottoms

Hopper Bottoms are ideal for storing and dispensing small components such as seed, grain, pellets, resins and powders. But finding the right size for your application can be difficult. We offer a variety of container sizes, funnel, and discharge configurations to customize your hopper bottom container to best meet the needs of your application.

Side or bottom discharge

Custom side discharge and bottom discharge hopper bottom containers are essential solutions for efficient material handling in various industries. They are designed to facilitate the quick and easy unloading of bulk materials. What sets them apart is their tailored features that can be customized to meet specific operational needs. Side discharge hoppers allow lateral unloading, making them ideal for applications where space is limited or when materials need to be directed into specific areas. In contrast, bottom discharge hoppers utilize gravity for efficient unloading directly from the bottom, ensuring minimal residue and optimal flow. Both options can be customized in terms of size, material, and discharge mechanisms, enhancing their versatility and effectiveness in transporting everything from grain and powders to aggregates and recycling materials.

Features and Benefits

- Multiple foot print options

- Collapsible or fixed wall designs

- Custom sizes

- Custom lids and accessories

Custom Funnels

Funnel design is a critical aspect of custom hopper bottom containers, significantly influencing their material flow and discharge efficiency. A well-engineered funnel shape enhances gravity feed, ensuring a smooth and uninterrupted flow of bulk materials while minimizing clogs and bridging. Customization options, such as varying the angle of the funnel, diameter, and outlet size, allow for tailored solutions that cater to specific material characteristics, such as density and moisture content. Effective funnel design can create hopper bottom containers that maximize throughput and reliability in diverse industrial applications.

Features and Benefits

- Multiple foot print options

- Collapsible or fixed wall designs

- Custom sizes

- Custom lids and accessories

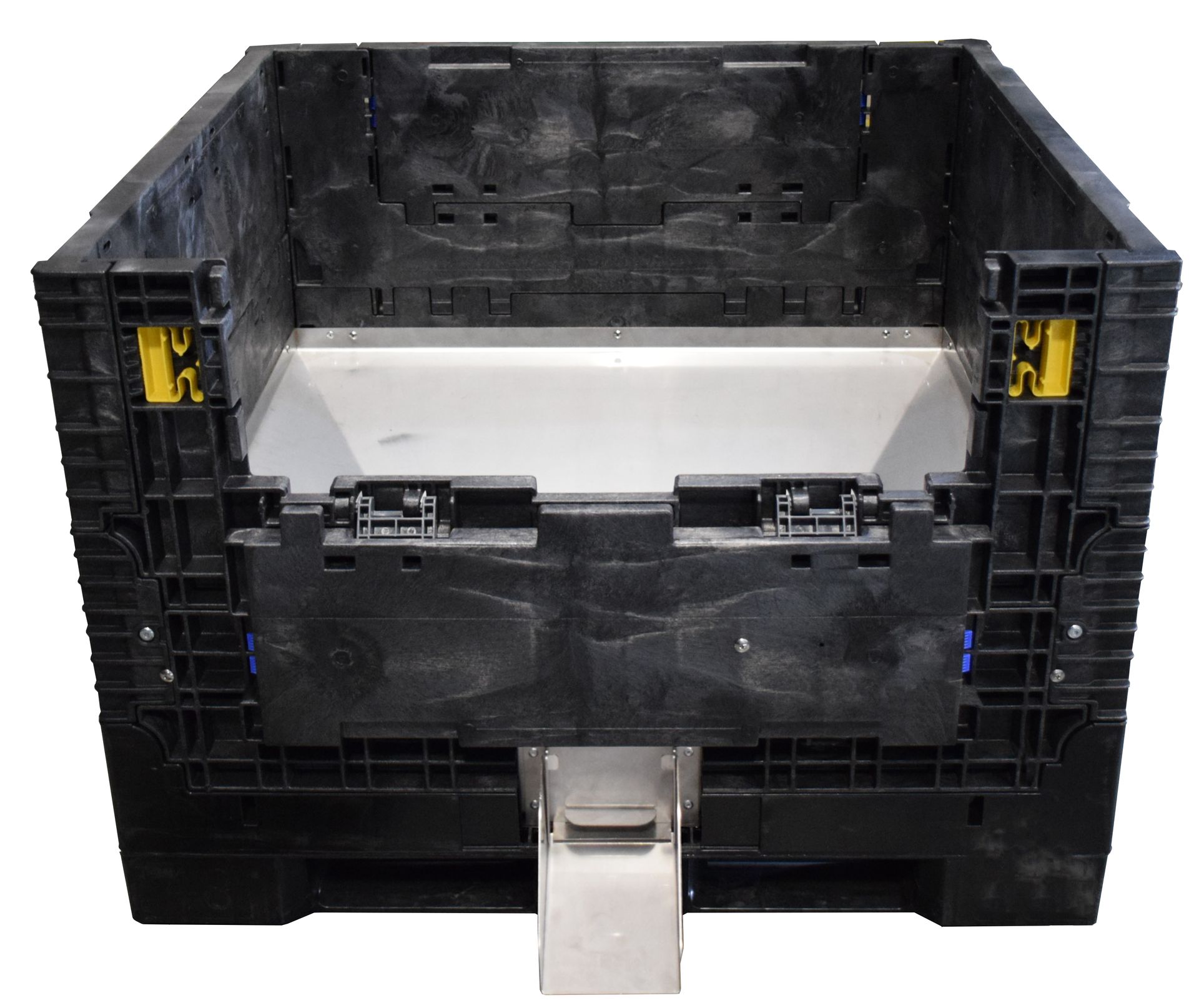

Collapsible Hopper Bottom

Custom collapsible hopper bottom containers offer a versatile, space-saving solution for transporting bulk materials. Designed to optimize storage and reduce shipping costs, these containers can be easily collapsed when not in use, making them ideal for companies with fluctuating storage needs. The collapsible design maintains the structural integrity required for efficient unloading, with features tailored to specific material types and handling requirements. These containers ensure smooth and efficient material flow by integrating customizable discharge options, such as side or bottom outlets. Additionally, the ability to customize dimensions, materials, and finishes further enhances their adaptability, making them a practical choice for various industries, from agriculture to construction.

Features and Benefits

- Multiple foot print options

- Side or bottom discharge options

- Custom funnel options

- Custom sizes

- Custom lids and accessories