Comparing Rotational and Injection Molding | RPP Containers

June 7, 2021

Rotational Molding vs Injection Molding

At RPP containers, we strive to provide the best in bulk. That is why a large majority of our containers are made by injection molding. However, before we get into that, let us go over what those are and the pros and cons of both.

What is rotational molding?

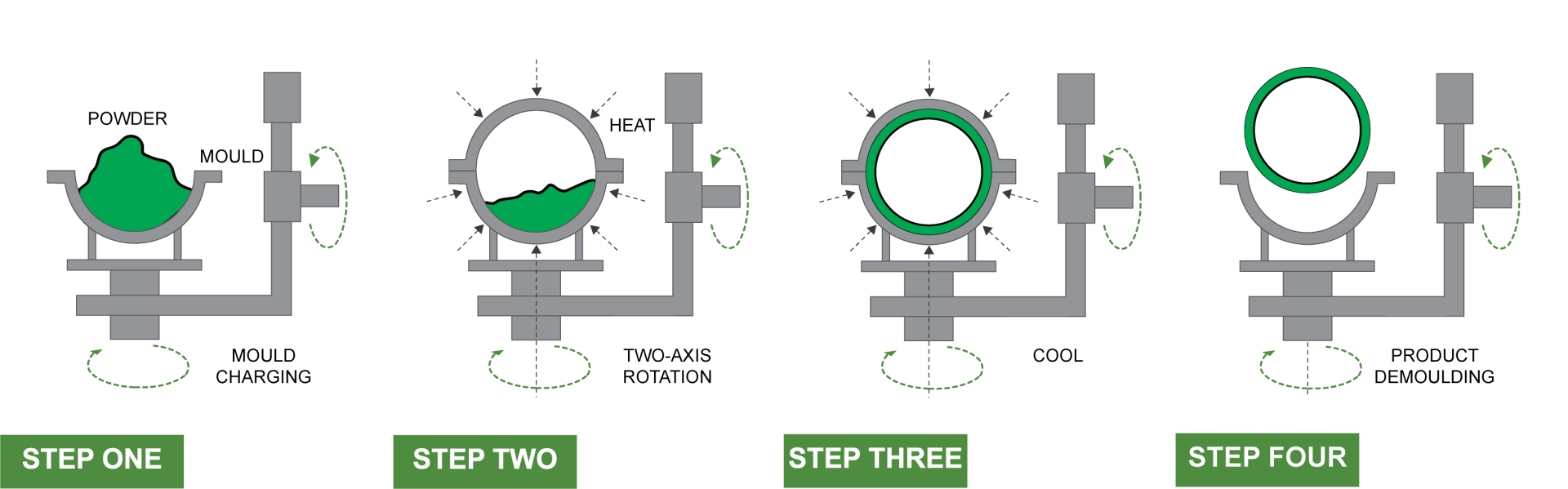

Rotational molding happens when plastic powder or liquid resin is added to a hollow mold and rotated bi-axially in an oven (similar to the process for a rotisserie chicken) until it melts and coats the inside of the mold cavity. Then, you must wait for the tool to cool and the plastic to solidify. Lastly, remove the plastic part from the tool and you have your part.

The advantage of this method is that the molds are much lower costs, affording greater variation or customizability in your products. Additionally, it takes much less time to develop a mold for rotational molding, shortening lead times on new products. However, if you are mass-producing a product or need it to have intricate designs, rotational molding may not be the best method. This method is used for things like canoes, yard flamingos, road cones, footballs, and planters.

What is injection molding?

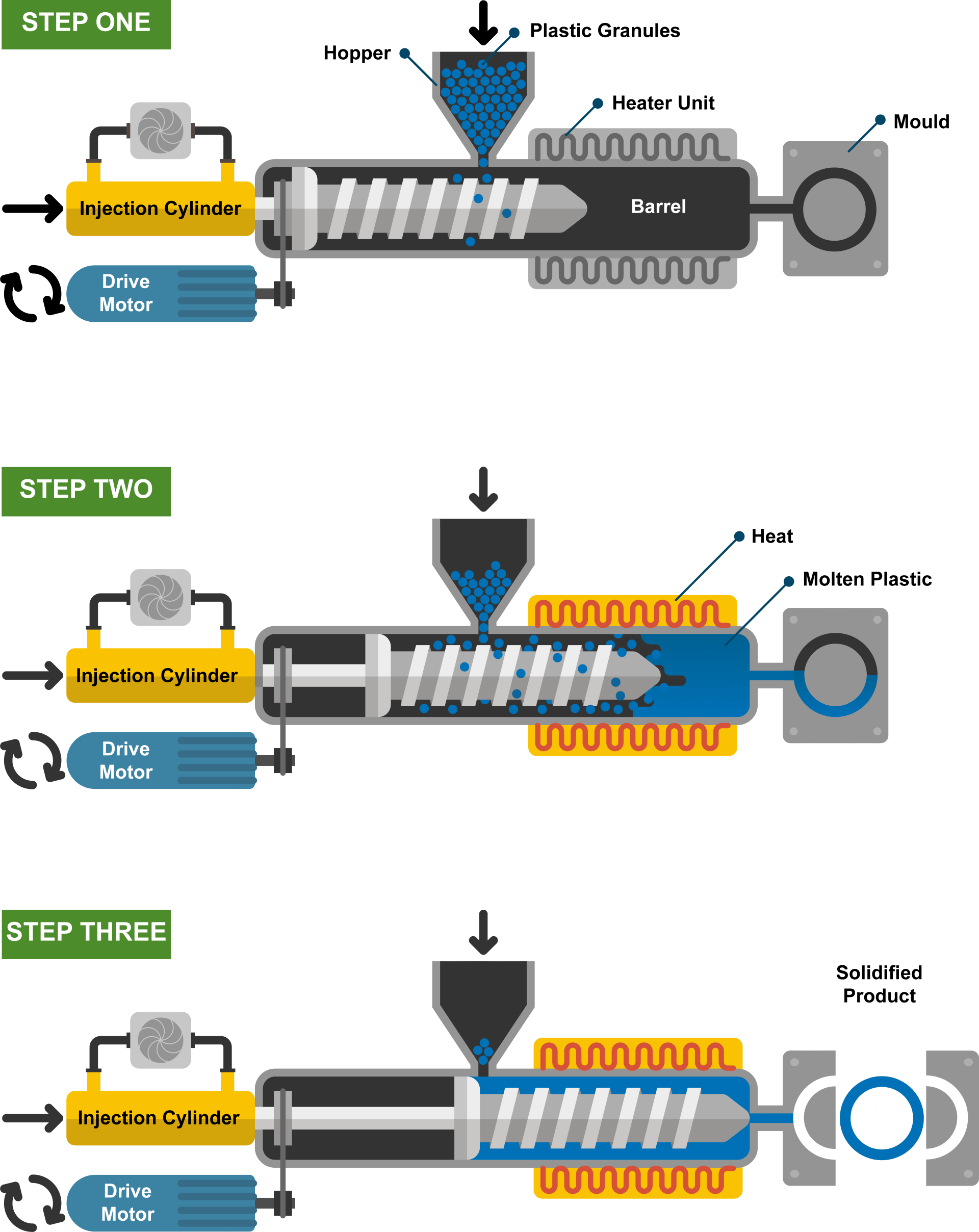

Injection molding occurs when a tightly held mold is injected with a melted plastic mixture in. The plastic is already hot when injected, and you must wait for it to cool down once it is injected into the mold. The molds for injection molding take a long time to produce, and it is a costly process. There is typically a lot of thought that goes into the design because there is usually more time and money invested into these.

Many or our containers have complex designs. This is because engineers are behind the scenes figuring out how to optimize durability while minimizing the plastic used to create longer lasting, stronger, and more inexpensive containers. Once the mold has been created, injection molding is far more efficient mass-producing products. We can deliver a larger number of products in less time and also save on labor costs. We chose to optimize costs and give you the best in

bulk containers

.

For a lot of our containers, we use a process called structural foam injection molding. This is a variant of injection molding where gas is added during the injection process, increasing aeration in the plastic. It has rigid skin and a more cellular structure. It lowers the weight of the parts and reduces stress on the plastics. These are great to use with forklifts as they are much less likely to snap from blunt force. These are the containers that do not have that sheen plastic look to them.

If you do not see a container that is exactly to your liking, we also offer customizable options. See more about there here

/news-events/customized-to-meet-your-needs

.

If you have any questions about how our containers are made feel free to give our sales representatives a call at (513) 489-2244, visit our

contact page

,

or use our chat feature on our website.

In the fast-paced worlds of agriculture, manufacturing, food and beverage, seed and feed, and logistics, efficiency isn't just a buzzword; it's a necessity. Handling bulk materials, such as seeds, grains, pellets, resins, and powders, can be a logistical nightmare if you're stuck with outdated or unreliable containers.

In today’s fast-paced agricultural industry, efficiency, food safety, and durability are more important than ever. One of the biggest improvements in produce handling has been the shift from traditional wooden crates to plastic harvest bins. Built with FDA-approved polypropylene and designed for maximum strength.