What is a double barn door container?

March 23, 2023

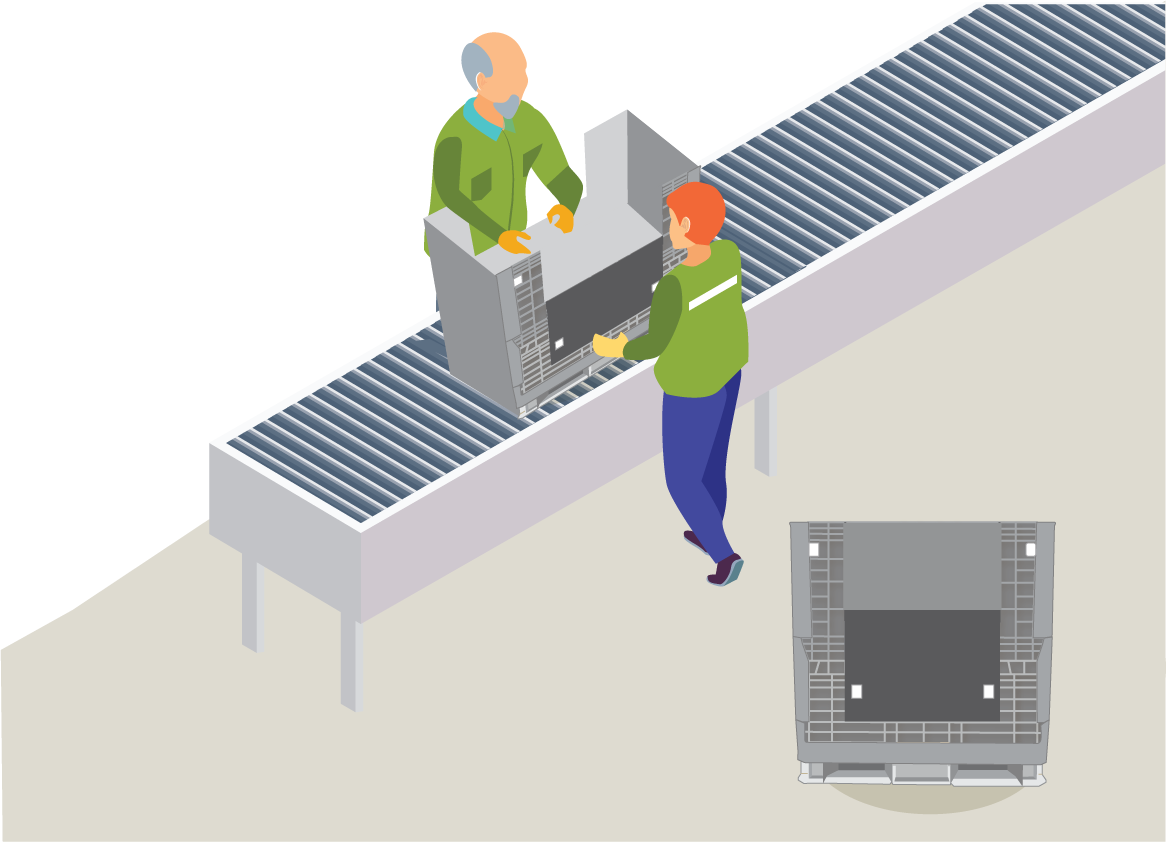

The Challenge: How to access products in a bulk container from both sides of an assembly line?

Our customer was having issues with their assembly line system. The containers they were using had drop doors for easier access into the container. Still, the workers loading and unloading the containers were experiencing difficulties reaching all the way to the bottom of the container as the drop doors were only half the height of the wall.

The container was loaded with cans of animal food along with heavy bags of litter and animal food, so when the heavier bags were at the base of the container, workers injured themselves trying to lift the bags up and over the drop door opening. The customer needed direct access to the base of the container and liked the idea of a barn door container, but our standard barn door container would not suffice as they needed access to two sides of the container, not just one. Another concern was that if the container was fully loaded and a worker opened a barn door, the items would fall out if they had shifted during transit, potentially causing injury.

The Requirements

The container needed to have access to the base of the containers on two parallel sides so that the workers could load and unload from both sides, making their process quicker and more efficient. They also needed the entire side of the container to be open and accessible, not just a portion of it. They did not want any walls or doors blocking or obstructing the entryway of the container while loading and unloading, which meant the existing drop doors would not work.

The customer had also requested that the barn doors have two half doors on each barn door so that the bottom half barn doors could be closed while the top half barn doors were open and vice versa to help prevent any items falling out when loading and unloading the top portion of the container.

The Solution

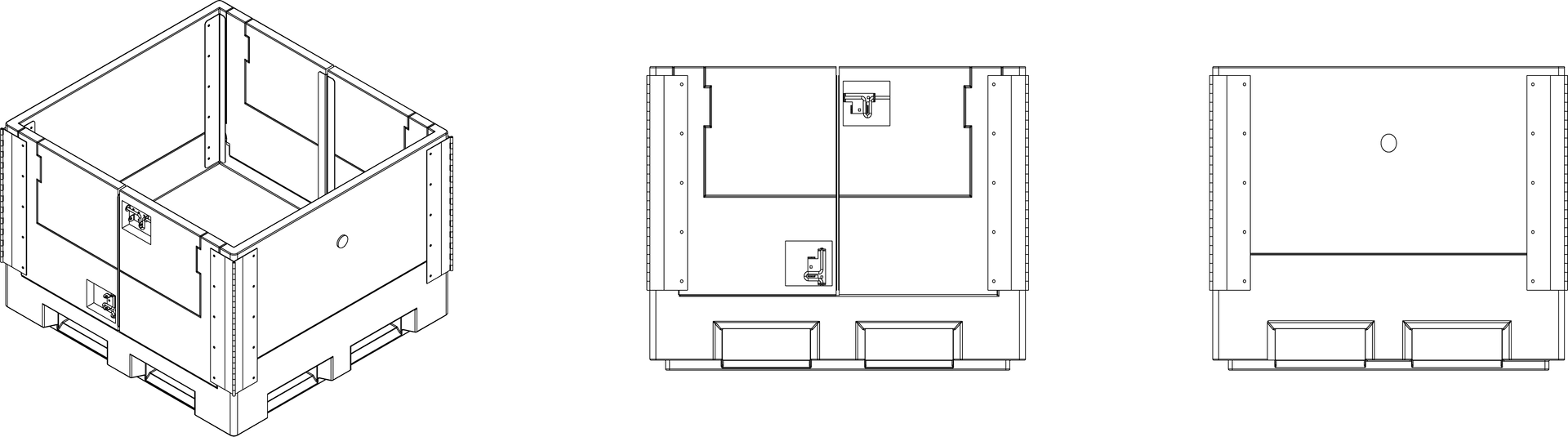

We initially created a 45” L x 48” W x 34” H container that had two barn doors on each 48” W. Each barn door also had two half-size barn doors giving it the capability to open just the top half of the wall, just the bottom half of the wall, or you could lock the half-sized doors back together and use them like a standard barn door container where the wall is made into two doors, and they open outward.

The initial prototype posed a few issues. Though the barn doors were great, they did not stay open during the loading and unloading process. We made a quick update and added piano hinges to the barn doors so that the doors could open and fold back onto the 45” sidewalls to ensure they were out of the way of the workers and the loading and unloading process. We also included magnets on the outside of the 45” sidewalls and on the outside of each barn door so that when the barn doors were open, the magnets would meet keeping the doors open until pulled shut. The customer also had us change to a standard barn door container instead of having half barn doors on each standard barn door. The half barn doors did not pose an issue, but the customer decided that their packing process would change instead of changing the design of the container.

After the customer’s testing process, the final product is exactly what the customer was looking for, making their assembly line issues disappear. The customer is now confident in their assembly line process, knowing their workers are safe loading and unloading. It will also be a quicker and smoother transition into the next phase of their assembly.

Do you have questions?

If you need help with a challenge within your packaging process, please contact the RPP Containers sales team, who can help you find the best solution to your specific needs.

In the fast-paced worlds of agriculture, manufacturing, food and beverage, seed and feed, and logistics, efficiency isn't just a buzzword; it's a necessity. Handling bulk materials, such as seeds, grains, pellets, resins, and powders, can be a logistical nightmare if you're stuck with outdated or unreliable containers.

In today’s fast-paced agricultural industry, efficiency, food safety, and durability are more important than ever. One of the biggest improvements in produce handling has been the shift from traditional wooden crates to plastic harvest bins. Built with FDA-approved polypropylene and designed for maximum strength.