Returnable Containers and embracing industry 4.0 warehouse optimization

The warehousing industry has witnessed a significant transformation in recent years, with the rise of e-commerce, labor shortages, and the constant need for efficiency driving the adoption of new technologies and strategies. High-velocity distribution centers have emerged as game-changer, providing businesses with a competitive edge by streamlining their supply chain operations. This article explores the top trends in warehouse optimization, focusing on the role of Industry 4.0,

returnable containers, totes, and

pallets in shaping the future of distribution centers.

High-Velocity Distribution Centers

Traditional warehouses are evolving into high-velocity distribution centers prioritizing speed, efficiency, and adaptability. These centers are designed to handle the increasing demand for fast order fulfillment, driven by the growth of e-commerce and changing customer expectations. To stay competitive, businesses must invest in warehouse optimization, leveraging the latest technologies and strategies to improve their operations.

Industry 4.0: The Future of Warehousing

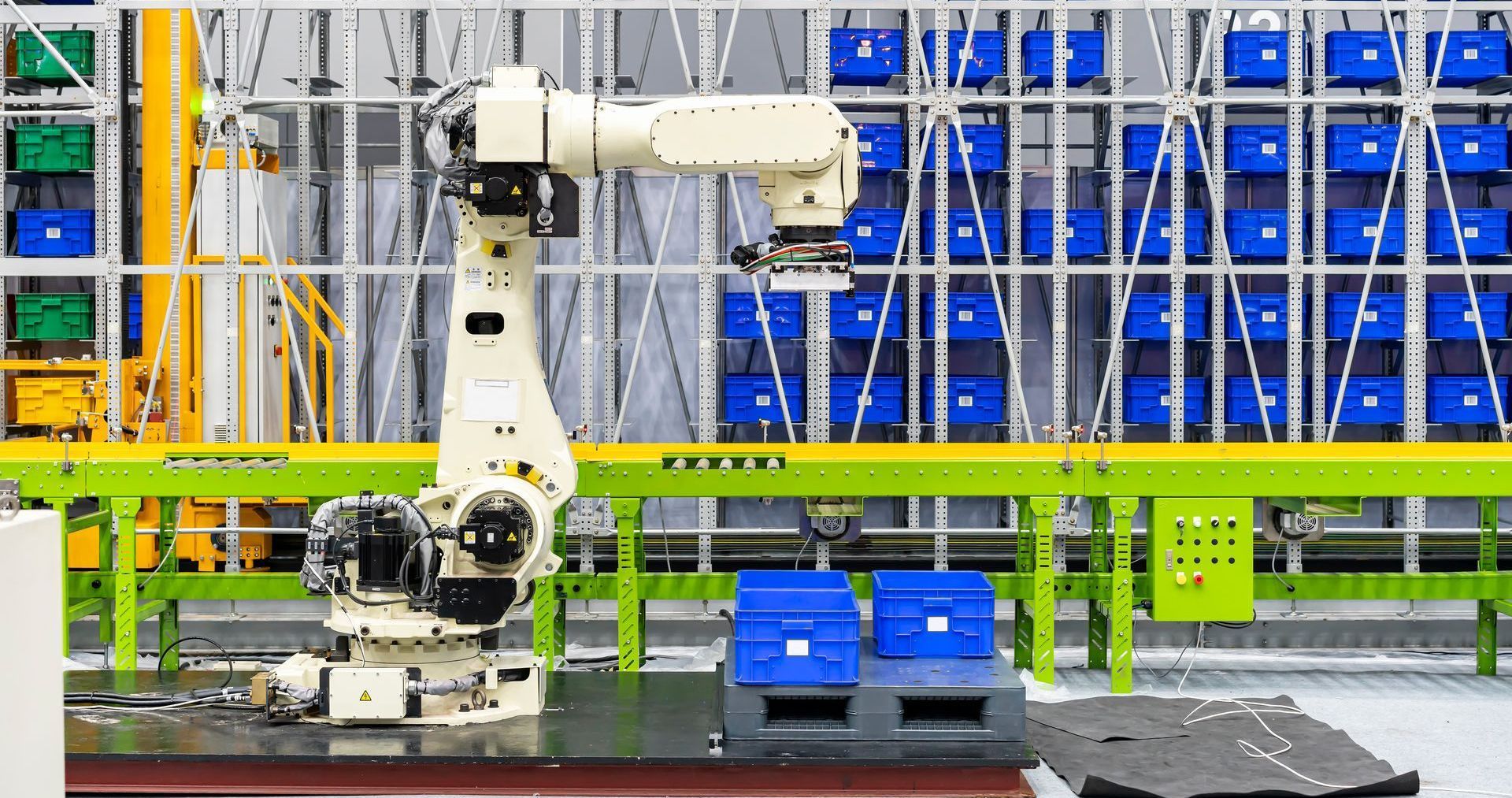

Industry 4.0 has become a key driver of warehouse optimization as businesses look to adopt advanced technologies to streamline their operations. This new industrial revolution is characterized by the integrating of the Internet of Things (IoT), Artificial Intelligence (AI), robotics, and other digital technologies into the warehouse environment. This integration enables the creation of adaptable systems that can work alongside humans, enhancing productivity, accuracy, and overall efficiency.

One of the most significant trends in warehouse optimization is the adoption of warehouse automation technologies. Automation helps businesses overcome labor shortages, reduce errors, and increase throughput. Some of the most common warehouse automation technologies include automated storage and retrieval systems (AS/RS), robotic picking systems, and autonomous mobile robots (AMRs). These technologies work in tandem with warehouse management systems (WMS) to optimize inventory management, order fulfillment, and overall warehouse operations.

Human-Robot Collaboration

As warehouses adopt more automation technologies, the role of human workers is also evolving. Human-robot collaboration is becoming increasingly important in warehouse optimization as businesses strive to balance the benefits of automation with the need for human oversight and decision-making. Robots and humans can work together to perform tasks more efficiently, with robots handling repetitive tasks and humans focusing on tasks that require critical thinking and problem-solving skills.

Warehouse Management Systems (WMS)

Warehouse management systems (WMS) are crucial in warehouse optimization, providing businesses with the tools to manage inventory, track orders, and plan efficient workflows. Advanced WMS solutions leverage AI and machine learning to optimize warehouse operations, helping businesses make data-driven decisions that improve efficiency and reduce costs.

The Internet of Things (IoT) is another key component of Industry 4.0 that is transforming warehouse optimization. IoT devices like sensors and RFID tags can be integrated into warehouse operations to collect real-time data on inventory levels, equipment performance, and environmental conditions. This data can be used to optimize warehouse processes, monitor equipment health, and improve overall efficiency.

The Role of Returnable Containers, Totes, and Pallets in Warehouse Optimization

Returnable containers, totes, and

pallets play a critical role in warehouse optimization, as they help businesses reduce waste, lower costs, and improve efficiency. These reusable packaging solutions are designed to be used multiple times, offering several advantages over single-use packaging materials.

Reducing Waste and Environmental Impact

One of the primary benefits of returnable containers, totes, and pallets is their ability to reduce waste and minimize the environmental impact of warehouse operations. By replacing single-use packaging materials with reusable alternatives, businesses can significantly reduce the amount of waste they generate, lowering disposal costs and reducing their carbon footprint. At

RPP Containers

we

purchase and recycle

HDPE plastic unwanted and broken plastic bulk containers.

Returnable containers, totes, and

pallets can help businesses lower their packaging costs. While the initial investment in reusable packaging may be higher than in single-use alternatives, the long-term cost savings can be significant. Reusable packaging solutions are designed to be more durable and can be used for many cycles, reducing the need for frequent replacements and lowering overall packaging costs.

Reusable packaging solutions can also contribute to warehouse optimization by improving efficiency in several ways. Returnable containers, totes, and pallets are often designed with standardized dimensions and features, making them easier to handle, stack, and store. This standardization can help businesses optimize their warehouse layout and streamline the material handling processes.

Returnable containers, totes, and pallets can be integrated into automated warehouse systems, allowing them to be easily tracked and managed. RFID tags and IoT devices can be attached to these reusable packaging solutions, providing real-time data on their location, contents, and condition. This data can be used to optimize inventory management and order fulfillment processes, improving overall warehouse efficiency.

Warehouse optimization is a critical factor in the success of modern distribution centers as businesses strive to meet the demands of a rapidly evolving market. The adoption of Industry 4.0 technologies, such as warehouse automation, IoT, and AI, is transforming the way warehouses operate, enabling the creation of high-velocity distribution centers that prioritize speed, efficiency, and adaptability.

Returnable containers, totes, and pallets are crucial in warehouse optimization, helping businesses reduce waste, lower costs, and improve efficiency. By embracing these reusable packaging solutions and investing in the latest technologies, businesses can create a more sustainable, efficient, and competitive warehouse environment.

Do you have questions? Do you have questions about

Reusable Bulk Containers? Call 1-800-945-8304 or Chat Live with one of our knowledgeable account managers Monday-Friday, 8 am-5 pm EST. You can also send us an email by visiting our contact page.