How do CenterFlow Seed Boxes Save you time and money?

CenterFlow Seed Boxes Sacks the competition

Modern and efficient, CenterFlow Seed Boxes are a convenient and effective solution for storing, handling, and transferring seed, grain, pellets, resins, powders, and other flowable materials. The construction from high-density polyethylene means the CenterFlow hopper bottom will not rust, peel, or splinter and can handle thousands of pounds per load. The smooth, funnel-shaped interior has a 35˚ angle that ensures a steady flow of product. CenterFlow Seed Boxes allow you to maximize your time by making it simple to monitor the amount of flowable materials when you need it with the adjustable slide gate allows one person to safely empty the hopper's contents in as little as 30 seconds. The versatile CenterFlow hopper bottom can be used in various applications, including agricultural settings for seed and grains or in an industrial application to store and dispense resin, pellets, and powders.

Traditional storage - Inefficient and not ecofriendly

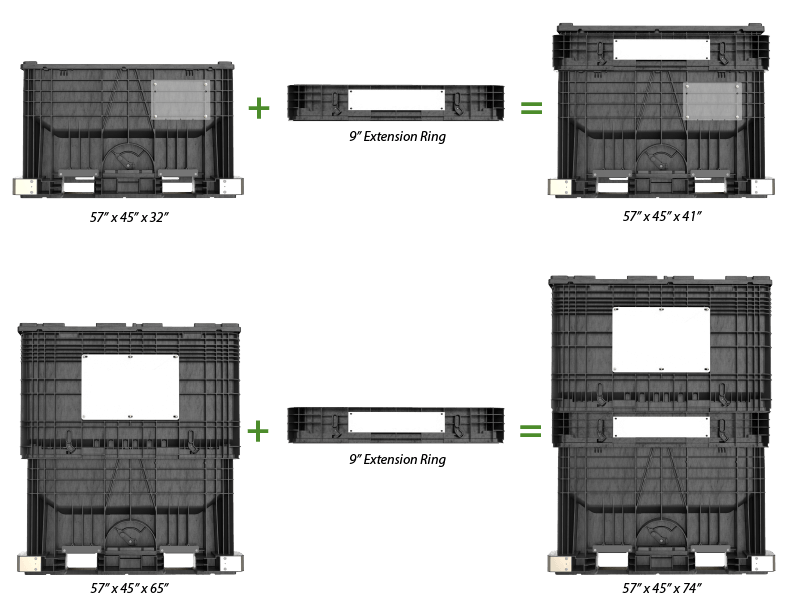

The right size for your application

DuraGreen CenterFlow hopper bottom containers are available in four heights using the 9" collar. The small CenterFlow hopper bottom is 57" x 48" x 32" and can hold up to 1,000 lbs. of product. Adding the 9" extender ring to the small 57" x 48" x 32" hopper bottom, you get the 57" x 48" x 41" medium CenterFlow hopper bottom. The medium 57" x 48" x 41" hopper bottom has a capacity of 1,500 lbs. The 57" x 48" x 65" is the large CenterFlow hopper bottom, is the standard industry size and can hold up to 2,500. The large CenterFlow hopper bottom is the standard top and bottom ring without the 9" extender ring. The extra-large 57" x 45" x 74" CenterFlow hopper bottom is the 57" x 45" x 65" large CenterFlow hopper bottom with the 9" extender ring added to it. The extra-large 57" x 45" x 74" CenterFlow hopper bottom can hold up to an incredible 3,000 lbs. of product. Suppose you currently own either a 57" x 48" x 32" or 57" x 48" x 65" CenterFlow hopper bottoms. In that case, you can purchase the 9" extension ring separately to add additional height to your hopper bottom container.

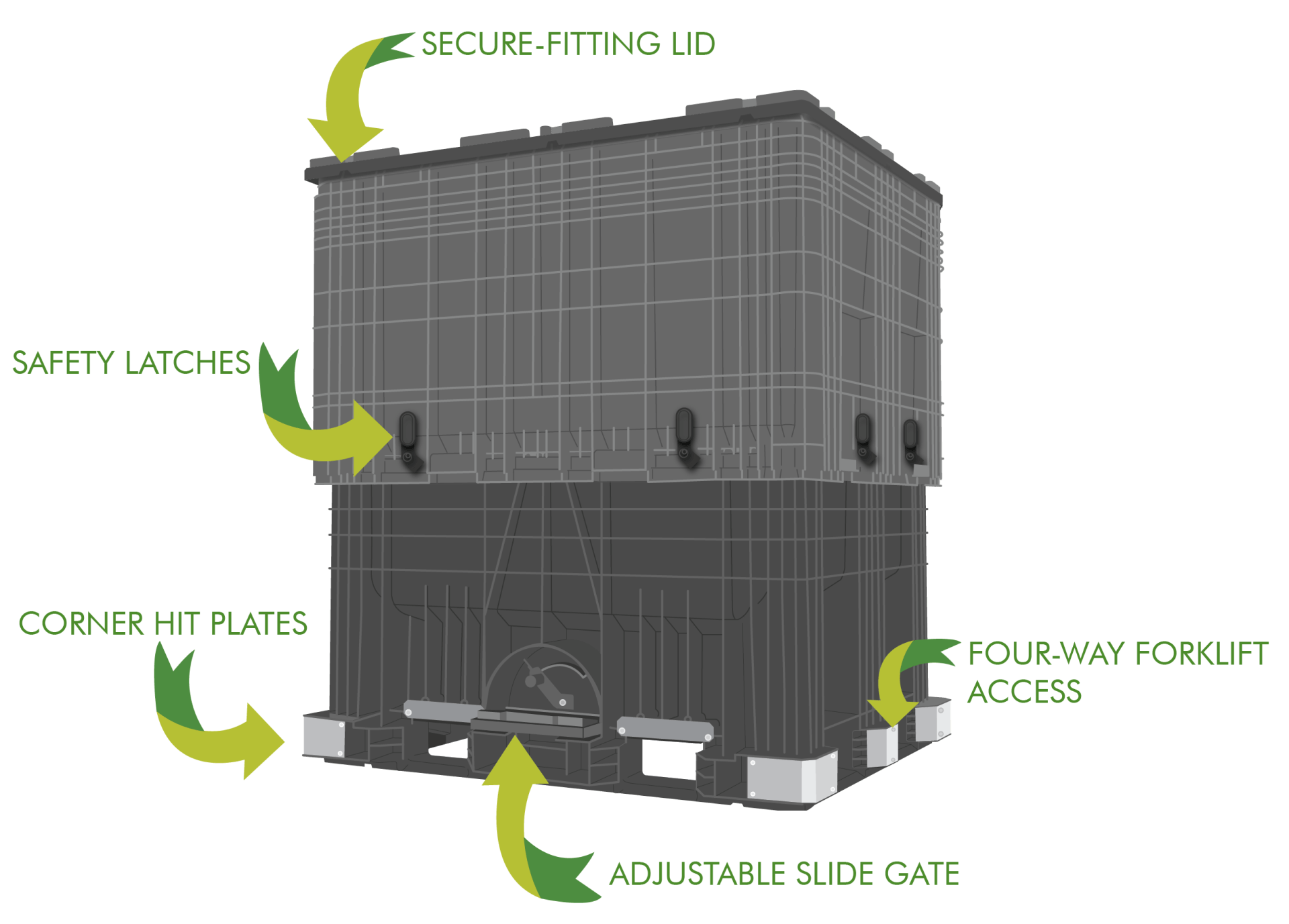

Safety first

- Secure-Fitting Lid – The lid features reinforced ribbing and corner stacking supports. The dome shape helps drain water from the top surface and provides extra protection against contaminants.

- Safety Latches – Latches lock the ring securely to the base.

- Adjustable Slide Gate – The slide gate allows one person to control the flow of contents safely.

- Four-way Forklift Access

– Allows entry from all sides for secure and efficient handling.

- Corner Hit Plates – Corner hit plates are made from galvanized steel and deflect forklift tines.

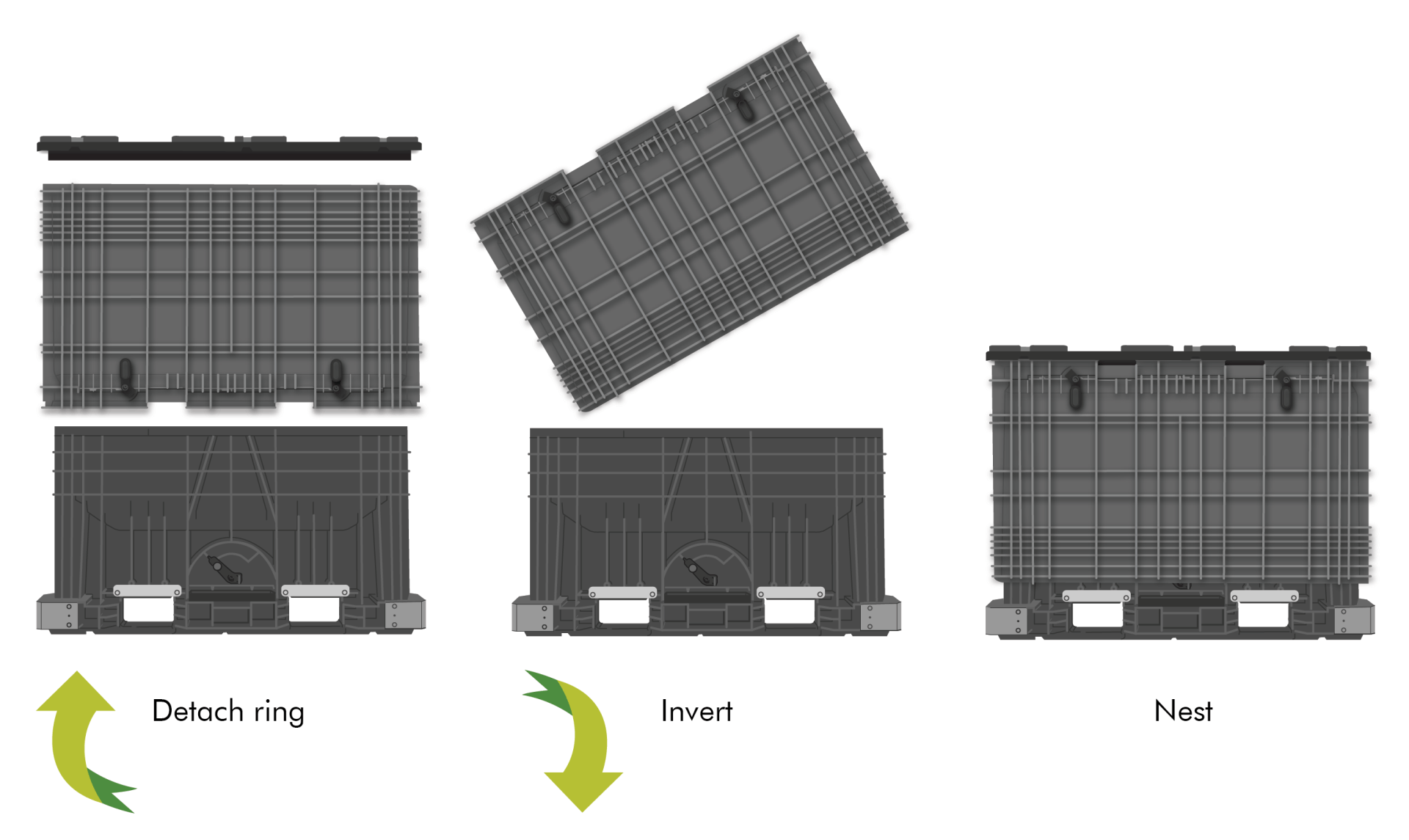

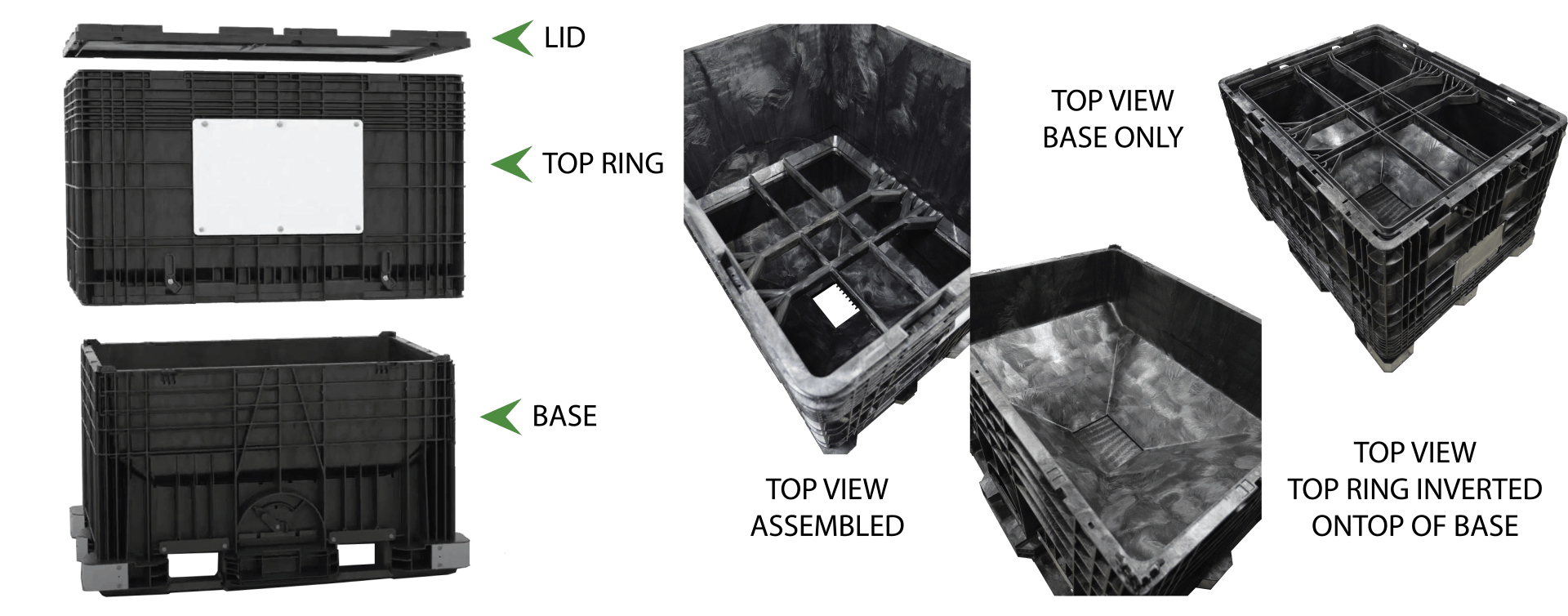

Efficient nesting storage

The CenterFlow hopper bottom is extremely efficient for storing and transporting products, but it is uniquely designed to maximize storage space by at least 40%. When empty, the CenterFlow Hopper Bottoms also can be "nested" to save even more space and helps to reduce the cost for them to arrive to you, and increases the return ratio if you ship them in a closed-loop system. The top half or ring of the hopper is pulled away from the bottom, flipped 180 degrees upside down, and reattached over the bottom section, reducing the overall height while still allowing it to be moved with a forklift.

When the CenterFlow Seed Box ships to you, it will be fully nested to reduce the space needed to ship. Even when fully nested, the seed box hopper bottom can be easily moved with a forklift and unloaded from the truck. They will have to be assembled to use. Luckily, it isn't too complicated, but you will need another person to help you get it into the correct position. When you remove the lid, you should see four crossbars running across the top of the opening, and the eight latches will be right below the top ledge. Straight down from the latches, you will find secure handholds at the top of the fork pockets. Utilizing these, you can lift the ring up and off the bottom section, separating the two pieces. With specialized forklift attachments, the process of assembling and nesting CenterFlow Hopper Bottoms can be safely and easily automated.

With the two parts disconnected, you have to rotate the ring around. Another set of handholds is at the top of this section, near the latches. These will help with the transition of the top half. Taking your time and being careful, pivot the piece so the crossbars are on the bottom. Set the section, keeping the long side with the long and short side with the short on the lower half. An indentation along what is now the bottom will sit over the base holding it in place.

The last thing to do is lock the eight latches, securing the top to the base. The lid can be placed back on top if needed. It is now operational and ready to be loaded. This same technique will work for the 65” and 74” versions.

Secure stacking and space saving nesting

57 x 45 x 32 CenterFlow Hopper Bottom

53' Trailer: 66 units assembled / does not nest

Stacking limit: Up to eight high 21.75' / does not nest

57 x 45 x 41 CenterFlow Hopper Bottom

53' Trailer: 44 units assembled / does not nest

Stacking limit: Up to six high 20.75' / does not nest

57 x 45 x 65 CenterFlow Hopper Bottom

53' Trailer: 22 units assembled / 44 units nested

Stacking limit: Up to four units high 21.25' assembled / up to four units high 12.85' nested

57 x 45 x 74 CenterFlow Hopper Bottom

53' Trailer: 22 units assembled / 44 units nested

Stacking limit: Up to four units high 24.25' assembled / up to four units high 15.85' nested

Do you have questions? Do you have questions about CenterFlow Hopper Bottom Containers? Call 1-800-945-8304 or Chat Live with one of our knowledgeable account managers Monday-Friday, 8 am-5 pm EST. You can also send us an email by visiting our contact page.

Are you looking to buy 25 Hopper Bottoms or less? For immediate pricing or to purchase 25 hopper bottoms or less, visit our online catalog BulkContainerExpress.com.