What are the 6 most common materials used for interior packaging dunnage?

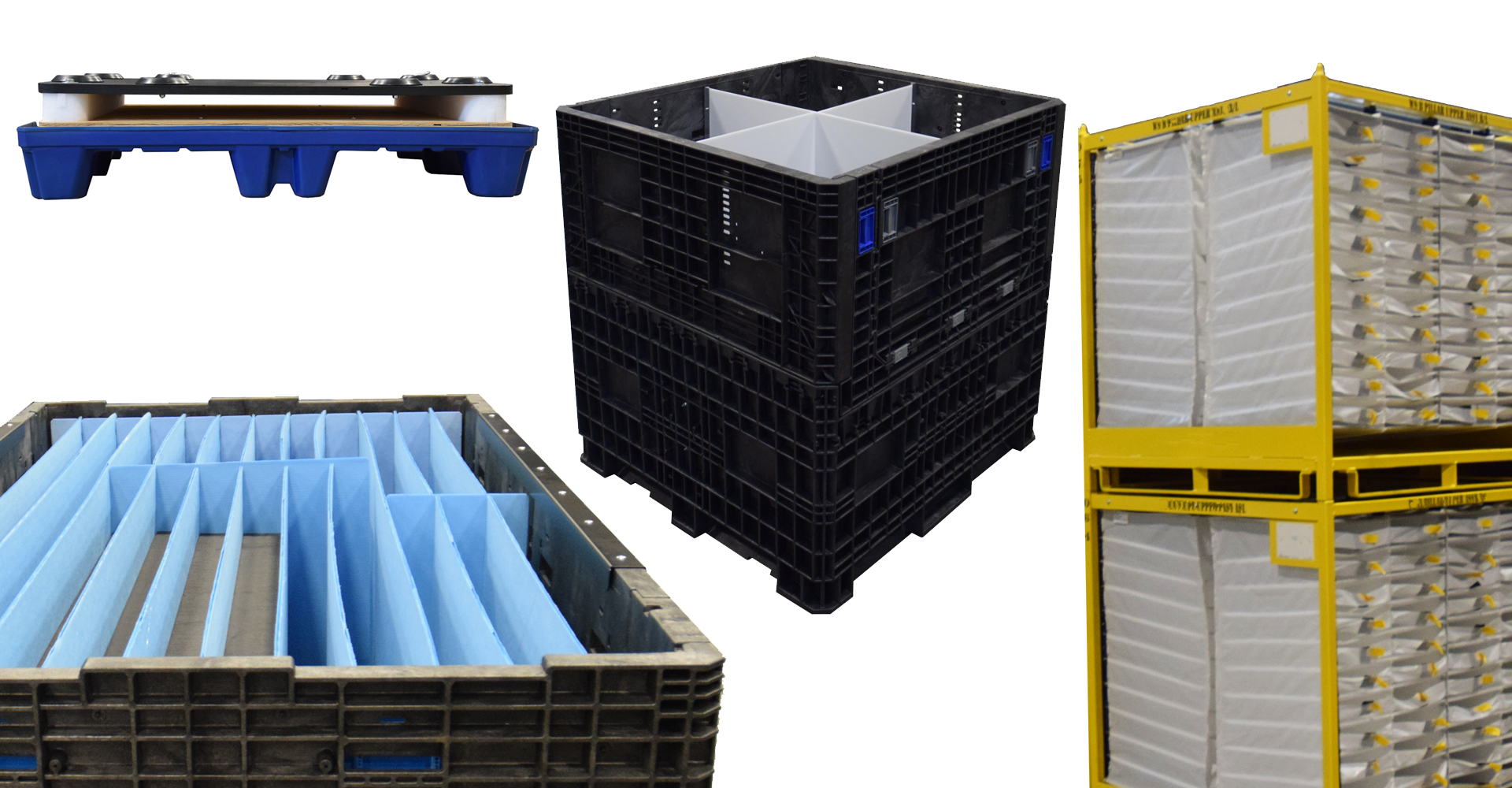

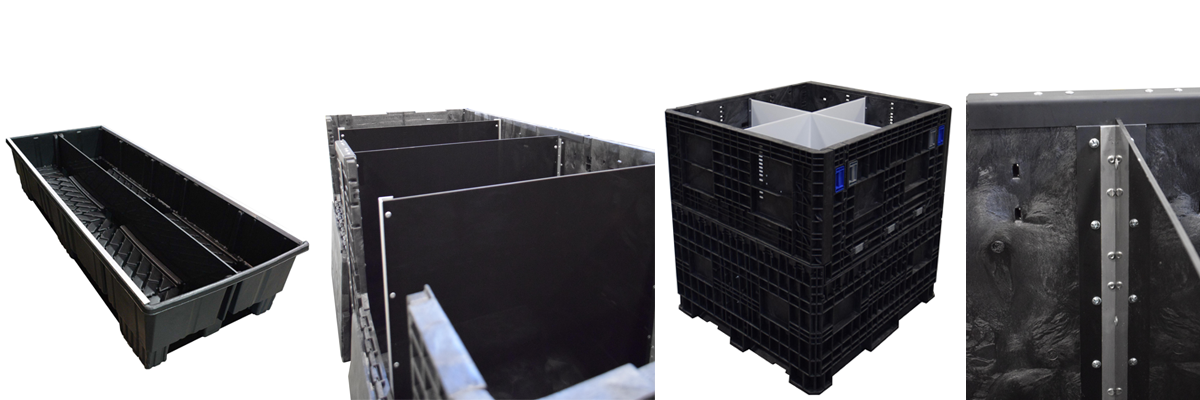

What is bulk container dunnage? The word "dunnage" is a term that describes packaging components that fit inside a

bulk container. Six popular examples of interior packaging components are blocks, boards, planks, foam, and plastic or metal bracing used to secure, protect, and support parts and products for and during transport.

What are the 6 most common materials used for dunnage?

Dunnage can be made from multiple types of materials or combinations of materials. At

RPP Containers, we use a wide variety of materials ranging from but not limited to corrugated materials, fabric, plastics, metals, foams, and wood.

Several materials can be used to create dunnage. The application's environment, the product's weight, storage time, and type of handling required are all factors considered when designing dunnage and what material or materials are required to give maximum protection to your products.

6 popular materials used for dunnage:

- corrugated cardboard/paper

- corrugated plastic

- foam

- solid plastics

- fabric

- steel and wood

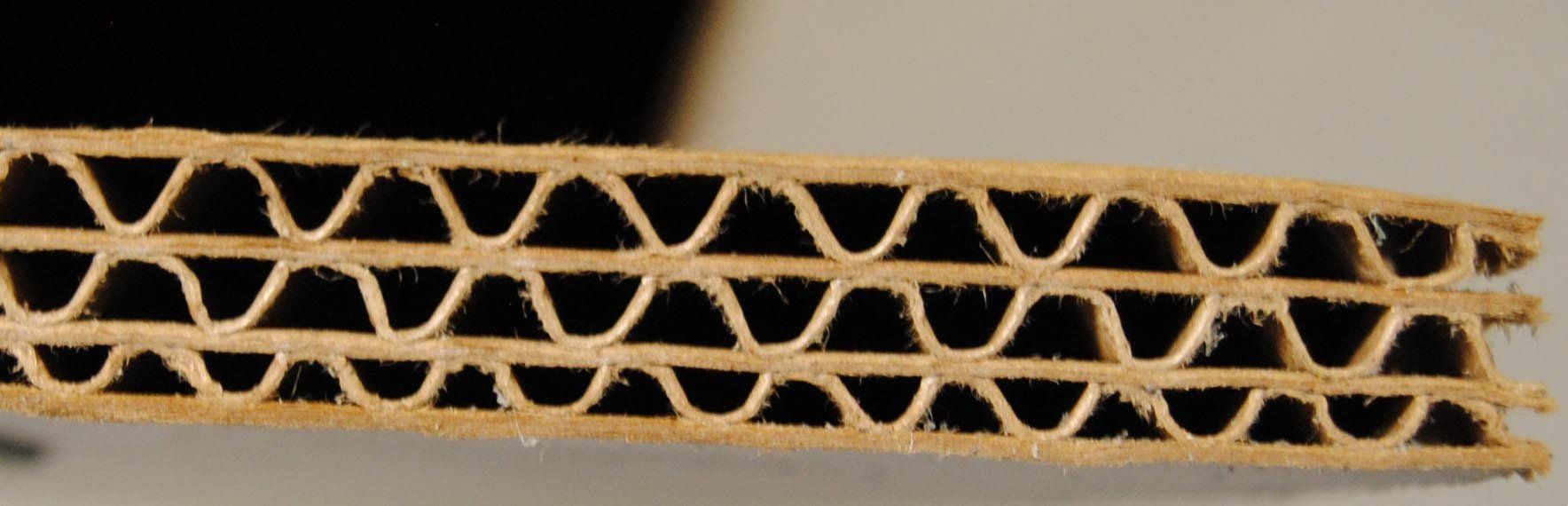

Corrugated Cardboard Dunnage

Corrugated cardboard is a paper-based material and is 100% recyclable. Corrugated cardboard is flexible and strong and is available in single, double, and triple-wall thicknesses. Corrugated cardboard is a lightweight and cost-effective option. Corrugated cardboard is traditionally used for partitions and divider dunnage. Corrugated dunnage keeps the product separated and in place so that during transit product will not move or make contact with other products and cause damage.

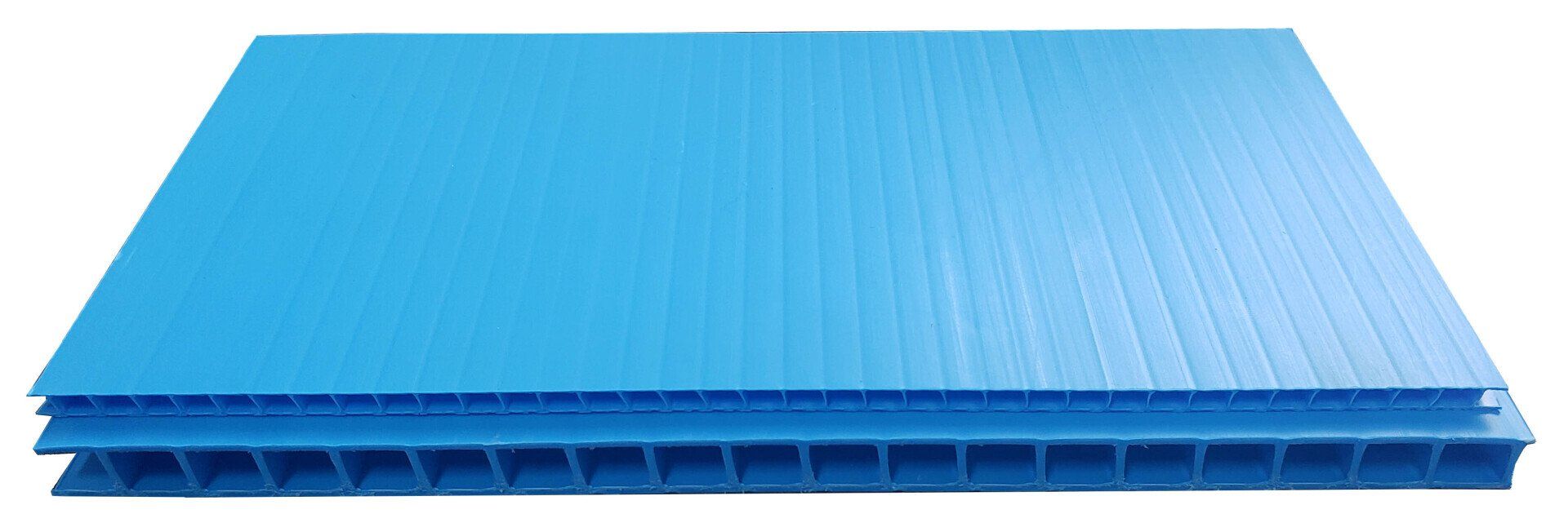

Corrugated Plastic Dunnage

Corrugated plastic is durable and reusable, unlike cardboard. Corrugated plastic is designed for repeated use and is resistant to puncture, tearing, and impact damage. Corrugated plastic is moisture resistant and will not mold, mildew, or rust. Corrugated plastic is easy to score, crease, fold, nail, staple, and drill. Corrugated plastic dunnage inserts can be designed to accommodate applications and industries where wood and cardboard can not be used.

Foam can be used as a divider and buffer between products. Foam dunnage is lightweight and provides shock and vibration protection. Foam can be easily cut to fit any shape of a container or product. The application determines the type of foam that is used. With foam being a lightweight material, it cuts down on a container's overall weight compared to other material options.

Solid plastic dunnage is made from high-density polyethylene, is ideal for heavier parts, has extreme durability, and is ideal for objects with sharp edges or parts. Solid plastic dunnage is used as a buffer between parts, absorbs shock, and is a popular option in the automotive industry. Solid plastic dunnage is weather resistant, will not mold or rot like cardboard or wood, and is 100% recyclable.

Fabric dunnage is versatile and flexible and offers capabilities that other rigid dunnage cannot. Fabric dunnage is available in multiple combinations. Industrial fabric dunnage is ideal for protecting uniquely shaped parts for storage and transit. Don't let the word fabric fool you. Fabric dunnage can be durable and strong enough to withstand wear and tear from repeated contact with sharp metal and plastic. Fabric dunnage must have a framework to support it. Fabric dunnage collapses to fit in the bottoms of containers for condensed loads and reduced return freight expenses. Reusable fabric dunnage is washable and easy to clean without applying specialty coatings or films.

Steel and wood are often used for blocking and bracing heavy and large industrial parts and components.